BLUF: Before washing your Apache, cover components and openings to prevent water intrusion and, after washing, always check for standing water and dry it up.

Photo by Charles Rosemond

Photo by Charles Rosemond

This article initially appeared in PS 741 (Aug 14), p. 26.

Before washing your Apache aircraft, don’t forget to bag and tie your electronic components to protect them from water like it says in the IETM’s caution statement. The same goes for the pitot static tubes. You don’t want water to affect the tubes so that you won’t be able to tell your airspeed and wind speed.

After a thorough washing of your aircraft, water can pool in certain areas. Not drying up that water invites corrosion. Stopping corrosion dead in its tracks requires that you look for water in the most likely—and unlikely—places.

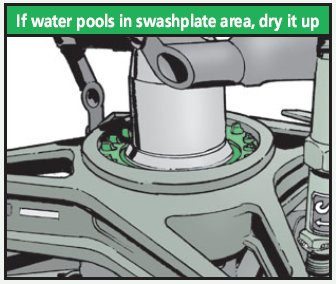

For example, after washing your AH-64, you need to check for leftover water in the rotating swashplate area. If you see water, use shop towels to soak it up. Allow the area to dry and then apply some corrosion preventive compound to the swashplate like it says in the IETM.

If water pools in swashplate, dry it up

If water pools in swashplate, dry it up

An aircraft wash should not turn into a major repair exercise, so take precautions to protect parts and components from water intrusion and corrosion.

Editor’s Note: Minor edits have been made to the original version of this article for clarity and brevity.