BLUF: The key to performing good aircraft maintenance is using the tools identified in the TM, not the unauthorized homemade tools created in the shop.

Photo by Charles Rosemond

Photo by Charles Rosemond

This article initially appeared in PS 790 (Sep 18); it has been slightly modified to reflect new information.

Mechanics, aviation safety action message, AH-64-07-ASAM-11, and the AH-64 IETM instruct you to check for a gap greater than .020 inches between the bearing cap and the retainer every 25 flight hours. If the gap cannot be reduced below .020 inches by reseating or replacing the retainer, the IETM and the ASAM tells you to remove the main rotor blade and the lead lag link assembly to replace the hub bearing.

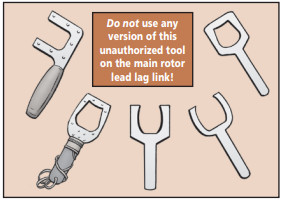

To accomplish the task, some maintainers have been using an unauthorized homemade or locally fabricated tool—the lead lag link bearing cup wrench, or spatula—to turn the bearing cap back into position during replacement or the 25-hour gap inspection. While this may save time, the tool could be masking internal wear that causes the caps to rotate in the first place.

The DEPOT lead lag link tool, PN 7-3640610003-53, and any version of it is not authorized at your level of maintenance and should be discarded. It's only authorized for depot-level maintenance.

When it comes to resourcefulness, most aircraft mechanics have a PhD. Using this tool may seem logical, but in this case, side-stepping maintenance procedures and using an unauthorized tool is not the smart thing to do. Variations of this tool have been found in many Apache maintenance shops.

Do not use any version of this unauthorized

tool on the main rotor lead lag link.

Remember, unauthorized tools and maintenance practices can cause more aircraft damage than they prevent. For more information, check out H-64-16-AMAM-02. With your CAC, log in at:

Pay particular attention to the Caution statement on page 5 of 8.