If you’re a spray paint technician assigned to a Logistics Readiness Center (LRC) or depot, have you heard of cavity wax? It’s a wax specifically designed for corrosion protection.

Cavity wax is applied to combat corrosion in hard-to-reach cavities of vehicles. Some of these cavities aren’t painted and when dirt and gunk accumulate there, it leads to corrosion.

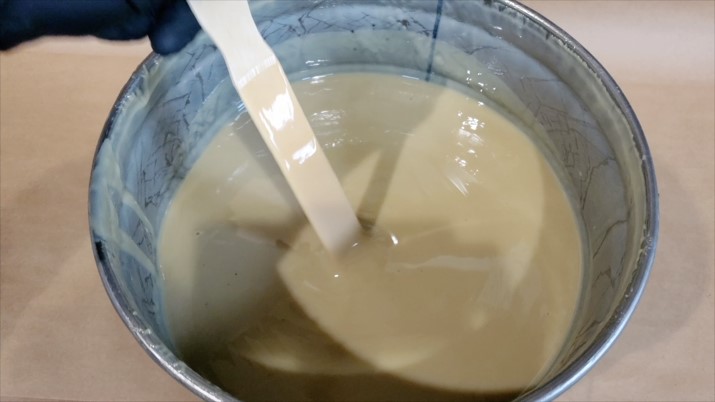

Cavity wax looks like thick paint.

Cavity wax

Cavity wax

Once cavity wax is applied to new equipment, it provides better corrosion protection because it’s applied to hidden cavities, which are often unpainted surfaces. The wax provides protection for several years after application, as long as it isn’t removed.

There are three (3) types of products that have been proven effective to treat cavities.

- Standard MIL-DTL-53022 CARC epoxy primer, NSN 8010-01-589-7077, brings a 1.25-gal kit, or NSN 8010-01-588-4312 will get you a 5-gal kit.

- NOX-RUST® R-491-115 doesn’t have an NSN. Order it under Commercial Item Description A-A-59295.

- TECTYL® 2423 HAPS Free Black doesn’t have an NSN. Order it under Commercial Item Description A-A-59295.

NOX-RUST® R-491-115 is best for vehicles not subject to deployment and redeployment wash requirements. That’s because it remains tacky after drying and may trap bugs, dirt or spores. It can be used on enclosed and sealed interior surfaces.

Both MIL-DTL-53022 Type IV primer and Tectyl® 2423 harden when dry so they can be used on all equipment and vehicles. MIL-DTL-53022 Type IV Primer is better for smaller spaces because it goes on thinner and dries faster.

After a year, the wax looks like this

After a year, the wax looks like this

Maintainers, it’s important to know that any grinding, cutting or heating with a torch can cause the cavity wax to run. Any work which raises a part’s temperature above 160°F should be done before cavity wax is applied.

The wax is applied to vehicles using a Graco® Merker® ESTM air-assisted airless spray-gun, PN 3A0732L, or Graco® SG2TM airless spray-gun, PN 24301. With either spray-gun, you’ll need a Graco® nozzle extension, PN 206496.

Past Challenges of Wax Application

Historically, the challenge in getting to cavities has been that most commonly sold spray lines couldn’t be fed or snaked to reach cavities. By adding a piece of flex line to the extension wand, the line is able to bend around corners and into cavities that were previously out of reach.

Nozzle extension and conical nozzle

Nozzle extension and conical nozzle

The cone-shaped nozzle on the extension wand helps to fully cover the cavity that the wax is sprayed into. Spraying with the cone-shaped extension wand may cause the wax to pool in some areas, but that’s fine. Spraying while pulling the wand from the cavity at a rate of about two (2) inches per second works best. Also, as the extension wand is pulled from a cavity, individuals using the spray-gun should release the spray-gun trigger to avoid overspray.

A future update to TM 43-0139 Painting Instructions for Army Material (Jun 14, w/Ch 1, Mar 16) will include the procedures for applying cavity wax. In the meantime, you can get even more info about cavity wax by contacting the DEVCOM GVSC Materials-Environmental, Coatings, and Corrosion team at:

Here's a link to the milTube video showing the application process.