Crewmen, your M1129A1 MCV, M1251A1 MCVV and M1252 MCVV Stryker’s RMS6-L 120mm mortar system needs a lot of attention to stay combat ready. Keep the following Do’s and Don’ts in mind so that your mortar does its job:

Do’s

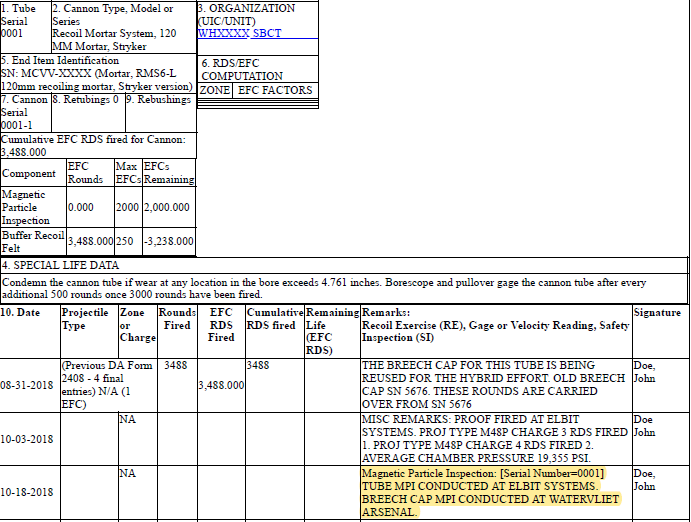

- Maintain gun card accuracy on DA Form 2408-4, Weapons Record Data Card.

Maintain gun card accuracy on DA Form 2408-4

Maintain gun card accuracy on DA Form 2408-4

- Follow operator and maintenance service/inspection intervals as outlined in TM 9-2355-311-13&P (Sep 16), TM 9-2355-363-13&P (Sep 16) and TM 9-1000-202-14 (Feb 99, w/Ch 8, Feb 19).

- Forecast service parts that are needed to maintain the RMS6-L and keep them in stock.

- Remove mortar tubes to clean and lube them to help prevent cannon tubes from seizing in the sleeve.

- Establish a unit SOP to remove and store cannon tubes in the arms room.

- Only mount a tube in its assigned/paired vehicle.

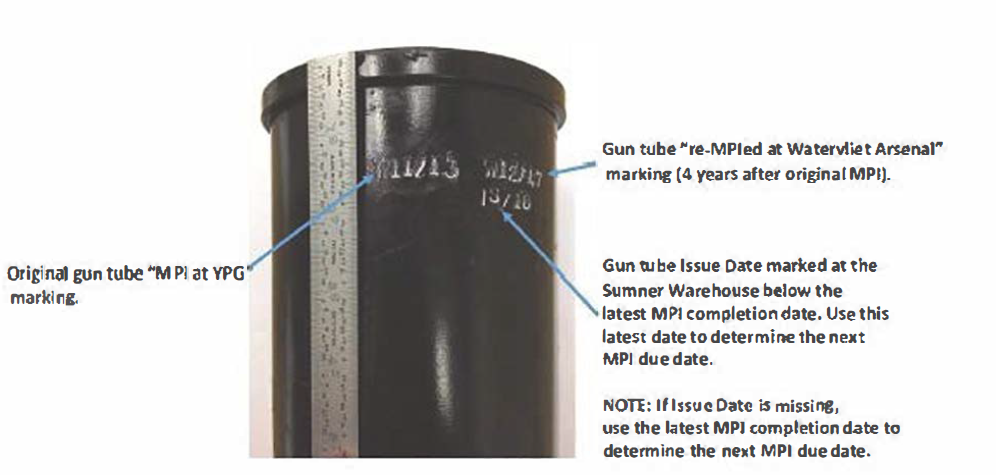

- Keep track of dates so you know when the magnetic particle inspections (MPI) are due. Make sure you:

- Implement GCSS-Army measures to track MPI dates

- Inspect six (6) months prior to MPI due date.

- Stagger MPI inspections to offset shortages in the supply system.

Keep track of MPI dates

Keep track of MPI dates

- Use TMs during command maintenance.

- Complete all pre-firing checks.

- Follow the inspection and condemnation criteria found in Appendix V of TM 9-1000-202-14.

- Maintain the M3 borescope kit. Be sure to use the right light bulbs and have good replacement bulbs. Note the following NSNs for lamp incandescent bulbs:

- NSN 6240-00-295-0907

- NSN 6240-00-922-7915

- NSN 6240-00-155-7866

- NSN 6240-00-092-3186

- Properly install staffs when connecting the M3 borescope.

- Install the retaining band with the clamp bolt at approximately the six o’clock position (facing down).

Install retaining band with clamp bolt at 6 o'clock position

Install retaining band with clamp bolt at 6 o'clock positionDon’ts

- Have missing or incomplete record information on gun cards (round count, borescope and pullover expiration and MPI date expiration)

- Fail to follow the TMDE calibration standards for special tools and test equipment (STTE).

- Improperly use and store STTE.

- Misplace TMs.

- Fail to conduct PMCS as outlined in TM 9-2355-311-13&P, TM 9-2355-363-13&P and TM 9-1000-202-14.

- Bypass pre-firing safety confirmation checks.

- Allow overdue service dates for the RMS6-L.

- Fail to follow pull-back exercise intervals.

- Fail to follow bleeding procedures on M3 pump, replenisher, recuperator and recoil system.

- Ignore proper bench bleeding procedures during recuperator installation.

- Forget to order pushing screw and nitrogen adapter for recuperator maintenance.

- But do make a note of the following NSNs:

- NSN 3040-00-929-4632, pushing screw

- NSN 4720-01-633-7354, nitrogen adapter

- Forget to requisition RMS6-L service parts prior to service dates.

- Mishandle basic issue items (BII), causing equipment damage on the RMS6-L.

- Have an unserviceable M3 borescope.

- Use the wrong light bulbs and damage pins and sockets on the M3 borescope.