This article initially appeared in PS 761 (Apr 16), p. 40-42.

Dear Editor,

We repair the small arms at the Ft Leonard Logistics Readiness Center (LRC). We think these suggestions on the M16 rifle and M4/M4A1 carbine will help operators, armorers and 91F repairmen get the most out of their weapons:

No cotton swabs!

Units are actually buying swabs and adding them to the cleaning kits. When Soldiers use the swabs to clean the bolt carrier key, the cotton comes off and plugs the key, and soon the weapon stops firing. The cleaning kits come with pipe cleaners and that’s what Soldiers need to use instead of swabs.

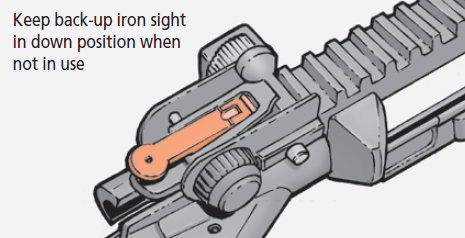

Protect the back-up iron sight.

We’ve had to replace as many as 100 in one week. Keep the iron sight in the down position whenever you’re not using it. Don’t stack weapons on top of each other. And, obviously, don’t drop weapons.

Keep back-up iron sight in down position when not in use

Keep back-up iron sight in down position when not in useCheck under trigger for trash.

When Soldiers do training where they crawl on the ground, dirt and pebbles often get stuck under the trigger. Even a tiny pebble can jam the weapon. You can get most trash out with a pipe cleaner or low pressure air.

Trash under trigger? Clean with pipe cleaner or low-pressure air

Trash under trigger? Clean with pipe cleaner or low-pressure air

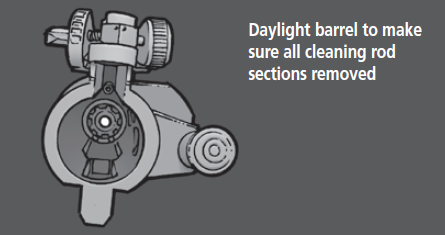

Make sure all of the cleaning rod is out of the barrel.

We’ve had several weapons explode because a cleaning rod section was accidentally left in the barrel. If you “daylight” the barrel (look through the chamber to see if you can see out the muzzle), you can be sure the barrel’s clear.

Daylight barrel to make sure all cleaning rod sections removed

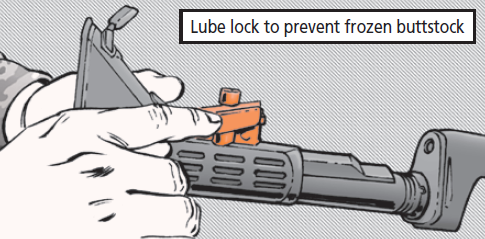

Daylight barrel to make sure all cleaning rod sections removedLube adjustable buttstock lock.

If the lock goes too long without lube, it freezes and then you can’t adjust the buttstock. When you do PMCS, put a few drops of CLP on the lock and work the buttstock back and forth.

Lube lock to prevent frozen buttstock

Lube lock to prevent frozen buttstockThoroughly clean the weapon before inspecting it or sending it to higher maintenance.

Carbon hides cracks and makes gaging inaccurate. Besides, support will send a dirty weapon right back to you for cleaning.

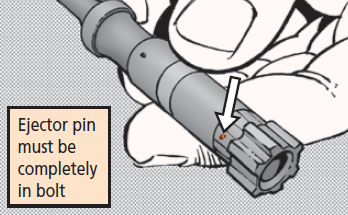

Armorers and 91Fs, install the ejector pin completely in the bolt.

If the pin’s not flush, count on it breaking off.

Ejector pin must be completely in bolt

Ejector pin must be completely in bolt

Victor Jackson

Mark Haggith

LRC

Ft Leonard Wood, MO

Editor’s note: We love to hear the voices of experience. Thanks.