Water accumulation in the hull causes corrosion, electrical shorts and other damage!

Water accumulation in the hull causes corrosion, electrical shorts and other damage!

Strykers across the fleet are experiencing height management system (HMS), central tire inflation system (CTIS) and anti-lock braking system (ABS) malfunctions due to fluids and water accumulating in Stryker hull cavities.

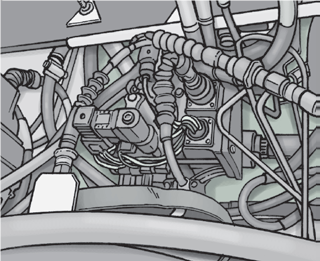

Components like the electronic control unit (ECU)...

Components like the electronic control unit (ECU)... ...and central tire inflation system (CTIS) can be damaged by fluid accumulation

...and central tire inflation system (CTIS) can be damaged by fluid accumulation

This fluid accumulation leads to electrical, mechanical and pneumatic failures. As a result, Stryker fleets end up non-mission capable (NMC) and fleet readiness takes a big hit, not to mention costing units a lot of money!

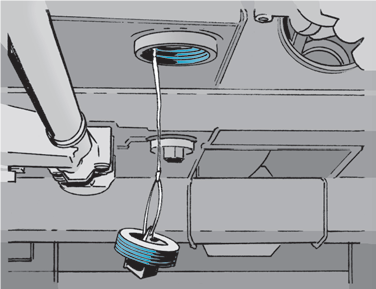

Soldiers can take action now to prevent these problems, mainly by removing the 15 hull drain plugs on flat bottom variants and the 13 drain plugs on double V hull variants. This allows any accumulated fluids to drain from the hull. Once the hull is free of fluids, replace the plugs.

The Stryker has either 13 or 15 drain plugs depending on the variant

The Stryker has either 13 or 15 drain plugs depending on the variant

Here are some good tips to help keep fluid accumulation levels at a minimum before these critical systems have bigger problems:

- The first step is to visually inspect under the vehicle for Class I, II and III fluid leaks such as oil, hydraulic fluid, coolant and fuel at all hull drain plug locations. Many times Soldiers skip this step in the AFTER PMCS outlined in:

- TM 9-2355-311-13&P (Sep 16) for the Stryker IAV

- TM 9-2355-326-13&P (Sep 16) for the NBCRV Stryker

- TM 9-2355-321-13&P (Sep 16) for the MGS Stryker

- TM 9-2355-363-13&P (Sep 16) and TM 9-2355-450-10 (Nov 20) for the double V hull Stryker.

If not caught in time, this oversight can lead to other system failures.

- Maintain the hull drain plugs so they don’t become seized to the chassis. Make sure to use anti-seize compound, NSN 8030-00-286-5453, on your hull drain plugs and chassis threads. This will make it easier to remove and install the plugs during PMCS.

Use anti-seize compound in drain plugs and hull chassis threads

Use anti-seize compound in drain plugs and hull chassis threads

- Dispose of contaminated fluids in approved containers and follow local authority and proper environmental procedures in your areas!

- Keep in mind when checking doors, hatches and grills during PMCS to check seals for damage. Having a good seal in place will help keep those unwanted fluids from entering the hull.

- Make sure to use an environmental cover, NSN 8340-00-577-5838, when your Stryker is not in use. That’ll keep water out of the engine intake system.

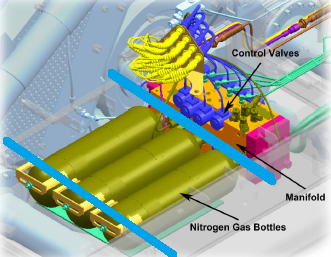

- Is your Stryker in “hot rod mode”? In other words, is one end of the vehicle higher than the other? Using the HMS to keep the vehicle level will help centralize those fluids in the middle of the vehicle hull. That’ll help you get to the fluids before critical components like the HMS manifold, CTIS manifold, ABS electronic control unit, ramp chains and fuel system manifold are found “snorkeling” under those floor boards.

Components can "snorkel" under water (marked by blue lines) causing damage

Components can "snorkel" under water (marked by blue lines) causing damage

- When conducting maintenance and lubricants are involved, make sure to follow the general cleaning instructions found in the Stryker IETM’s Field Maintenance Procedures under Storage Equipment Components once the job is complete. Not cleaning up the fluids and leaving them in the hull can lead to other issues. It could also be confused with a Class I, II or III leak.

- Take extra precautions when running your Stryker through the wash rack. When using high-pressure water, remember not to spray water into the engine bay fan and intake and exhaust system. And don’t spray water on or in the personnel and engine coolant circulating heater (PECCH) exhaust port and weapon systems. They do not like water!

- In cold climates, remember to check that fluids are not frozen under floor boards. If they are, it’s just going to take extra time to thaw out those blocks of ice.

Note: If you’re seeing fluid contamination in your wheel drives, it might be time to take a look at those de-aerator tanks to see if water is entering the vent lines.

The bottom line is that accumulating fluids and water intrusion are harmful to the Stryker fleet. Taking these precautions will ensure unnecessary fleet down time, save your unit some money, and help keep the supply system stocked with parts that are ordered a lot due to system failures caused by water intrusion.