There’s a right place and a wrong place (or many wrong places) to stow components of your grader. Keep these “proper place” reminders in mind while operating and maintaining your 120M road grader.

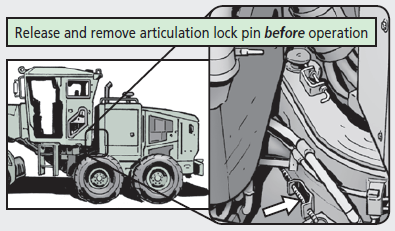

Articulation Lock Pin

The articulation lock pin keeps the grader from articulating when installed. When you leave the work site, pull back on the spring rod to release the pin. Make sure you stow the pin in its proper place: in the rear frame pocket. Don’t keep it in the cab or you’ll soon be buying a new pin.

Release and remove articulation lock pin before operation

Release and remove articulation lock pin before operation

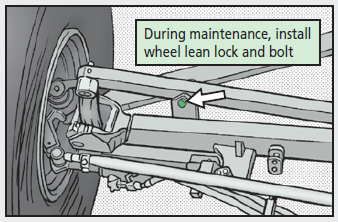

Wheel Lock Bolt and Nut

Mechanics, you’re supposed to use the grader’s wheel lean lock bolt and nut to secure the left front axle during maintenance. That keeps the wheel from tilting.

During maintenance, install wheel lean lock and bolt

During maintenance, install wheel lean lock and bolt

When you’re finished, make sure you remove the bolt and nut, screw the two together, and stow them in their proper place: the grader’s BII tool box. Don’t toss ‘em in the cab, or they’ll end up lost!

And remember: The wheel lean lock is to be used only during maintenance, not for shipping or storage.