BLUF: If you can't easily hand tighten a lug nut to the stud, then either the lug nut or the stud is probably bad. Here are steps to perform the task correctly.

Soldiers, IETM 9-2320-387-13&P (Mar 21) tells you to hand tighten lugs nuts before you reach for that impact wrench when you’re installing a wheel onto the geared hub of your HMMWV. That’s because if you cannot easily hand tighten a lug nut to the stud, then either the lug nut or the stud is probably bad.

Once you have the wheel off the vehicle, make sure studs and nuts are properly cleaned and inspected before you attempt to hand tighten the lug nuts to the studs.

Clean and Inspect Lug Nuts and Studs

Do the following as you clean and inspect lug nuts and studs:

- Use a wire bush to remove debris and paint from studs. Then clean the studs with soapy water and allow them to dry completely.

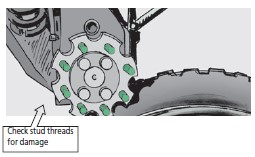

- Visually check for studs that are cracked, broken, rusted, pitted, bent or loose. Also look for stud threads that are worn. Replace all worn or damaged studs.

Check stud threads for damage

Check stud threads for damage

- Clean the lug nuts in soapy water and allow them to dry completely.

- Visually check for lug nuts that are cracked, rusted or have worn threads. Replace all worn or damaged lug nuts.

- Don’t add anti-seize compound to the studs or lug nuts.

Hand Tightening Lug Nuts

Once you’ve inspected and cleaned the studs and lug nuts, place the wheel back on the gear hub.

Lug nuts have to be hand-tightened gradually and in the proper sequence to avoid bending or breaking the studs. Follow the sequence shown below.

Tighten and torque lug nuts using this pattern

Tighten and torque lug nuts using this pattern

Once all the lug nuts are hand-tightened, you can tighten the lug nuts to 90-110 lb-ft of torque. As always, be sure to follow the guidance in the appropriate TM for your vehicle when conducting maintenance.

Related tire article:

HMMWV: New Winter Tire Assembly